KILN FURNITURE

KILN FURNITURE

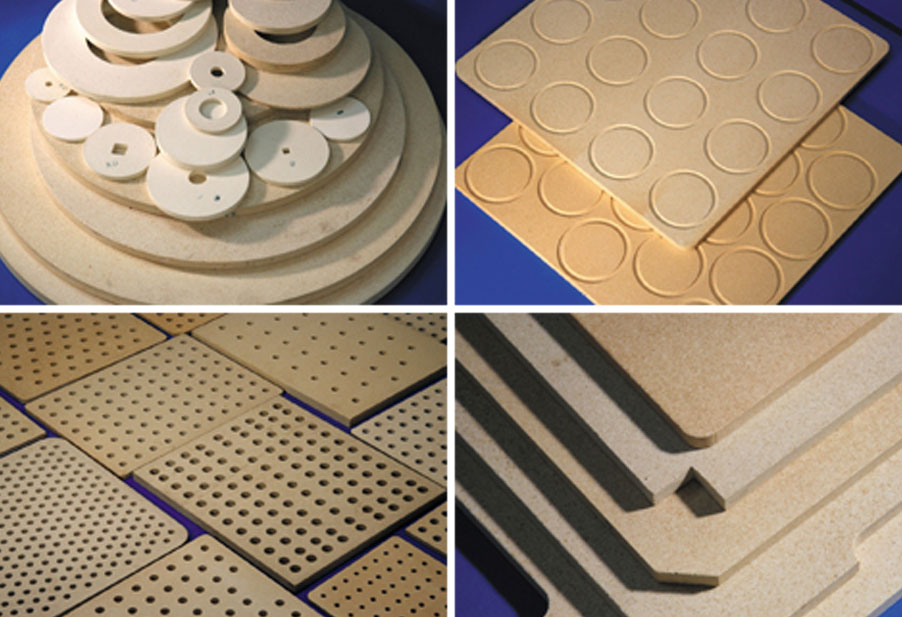

Plain Batts

Plain Batts are the most common type of primary kiln furniture, usually produced by semi-dry pressing, but can also be made by pressure-casting. Extruded batts can be split into ten sub-categories as follows: Extra Large Batt, Extra Thin Batt, Plain Batt, Perforated Batt, Grooved Batt,Trapezoid Batt, Recessed Batt, Full Disc, Half Disc and Special Batt.

Extruded Batts

Extruded batts have holes running the length of the cross section and are manufactured using high pressure vacuum extrusion, before being cut and surface-ground to guarantee the highest standard of flatness and dimensional accuracy. In June 1999, Trend developed the technology to produce extruded batts and became the first Asian manufacturer. Our extruded batts are now amongst the leading products in Asia, and are of a better quality than similar products made in China. They are used mainly in the sanitaryware and glass panel industries, but can be found in a number of applications including the biscuit and glost firing of tableware.

Plain Supports

Plain Supports are classed as Primary Kiln Furniture and are used as supports for pressed and extruded batts. These are normally manufactured by semi-dry pressing but can also be made by plastic-pressing or casting. Plain supports can be split into six sub-categories as follows: Cuboid Support, I-Shape Support, Adjustable Support, Support with Bases, Support Block and Special Support.

Extruded Tubes

Extruded tubes are classed as primary kiln furniture and are used as supports for plain and extruded batts. They are made by high pressure vacuum extrusion and occasionally by pressure casting. Extruded tubes can be split into six sub-categories based on shape and length as follows: Long Extruded Tube, Round Extruded Tube, Elliptic Extruded Tube, Square Extruded Tube, Rhomboid Extruded Tube and Special Extruded Tube.

Fittings

Fittings are classed as primary kiln furniture and are used as connectors, locators, supports and interlocks between tubes, beams and batts. The size of these products is not usually very large, but they are an integral part of a kiln build-up. Fittings can be split into three sub-categories as follows: Caps and Fittings, Splicer and Special Collar.

Secondary Kiln Furniture

Secondary Kiln Furniture refers to a wide range of products used in the tableware industry to support and protect ceramic products, usually coming into direct contact with the ware. There are several types of tableware, with thousands of shapes for numerous applications. This means that secondary kiln furniture is the most complex of all our product ranges, with the biggest variation in shape, size and material, making it the most difficult to manufacture. Choosing suitable secondary kiln furniture can help greatly increase the yield, increase kiln load, reduce fuel consumption, reduce labour and thereby lead to significant cost savings. Through the experience gained by working together with has made significant progress in the development of secondary kiln furniture, and can boast the most complete range of kiln furniture solutions of any supplier.

Saggars and Crucibles

Saggars and Crucibles, although they are quite different products, have been grouped together as they are both used as containers. Saggars are usually larger and used to protect or support products during firing, for example in the glost or biscuit firing of tableware, or for powder calcination, etc. These products can be made by semi-dry pressing, plastic pressing and casting. Crucibles are smaller containers used for the melting of materials, e.g. minerals and glass. Saggars and crucibles can be split into five sub-categories as follows: Round Saggars, Square Saggars, Special Saggars, Round Crucibles and Special Crucibles.

Sanitaryware Kiln Furniture

Sanitaryware Kiln Furniture is used to support for sanitaryware items during firing. As the support must fit the shape with the ceramic product, many of the designs are bespoke and complex, and are made by cutting and drilling products, or by pressure casting or plastic pressing. Sanitaryware kiln furniture can be split into six sub-categories as follows: Wash-Basin Setter, Cast Stool, Special Setting Leg, Special Setting Support, Special Setter and Special Accessory.

Heavy Clay Kiln Furniture

Heavy Clay Kiln Furniture is used in the clay brick and roof-tile industries. Due to the heavy loads involved, this type of kiln furniture has its own special material and structure, with many different shapes to accommodate a wide range of products. The production methods used to manufacture these products are semi-dry pressing, high-pressure vacuum extrusion and pressure casting. Heavy clay kiln furniture can be split into five sub-categories as follows: H-Cassettes, U-Cassettes, Special Cassettes, Viaduct Blocks and Special Shapes.

Kiln Accessories

Kiln Accessories are refractory products used in the kiln structure (roof and wall) or on the kiln car base. Thanks to Beijing Trend's years of research and cooperation with many international kiln companies, cordierite-mullite kiln furniture materials have been developed for use in the kiln structure to help solve the problem of kiln dirt from insulating bricks and ceramic fibre linings. This significantly increases production yields during the firing of ceramic products, especially for intermittent kilns (Shuttle kilns), where linings are subject to repeated thermal cycling. Cordierite-mullite imparts good thermal shock resistance and can improve the longevity of insulating firebrick and ceramic fibre linings.

Other Products

Other Products are all those items currently that do not belong to the ten main categories, as well as some factored goods. These can be split by shape and material into four sub-categories as follows: Refractory Bars, Interlock Spheres, SiC Products and Special Kiln Furniture. SiC Products are manufactured by a partner of Beijing Trend, but are strictly checked and conform to Trend's quality system. These products are mainly Silicon Infiltrated Reaction Bonded Silicon Carbide (SCS / SiSiC), Recrystallized Silicon Carbide (SCR / RSiC) and Oxide-bonded Silicon Carbide (SCO).

Cordierite Chamotte

Cordierite Chamotte is composed of 40 - 55% Cordierite, 30 - 50% Mullite and a glassy phase of 10 - 15%. Its main characteristic is its low co-efficient of thermal expansion (At 20 - 1000oC it is between 2.2 and 3.0 x 10-6K-1), and is therefore suitable to be used in the manufacture of industrial ceramics, refractory shapes, castables, and as a filler. Typical uses are: High thermal-shock resistant refractory and insulating bricks, ceramic burners, honeycomb ceramics, anti-exfoliating casting material, spray mixes, and it can also be added into the recipes of large cast sanitaryware items to reduce the fired contraction and the expansion co-efficient in order to increase dried and fired yields.